Technological Superiority

Improve test accuracy , save quality cost , and shorten

test cycle;

Effectively integrate product line with the existing one ;

High traceability: product quality data can be stored to

a database such as Access , Oracle, and can also be

exported to excel ( automatically switch to local

database in case of internet failure , and automatically

switch back to internet and use remote database if

internet works normally ).

High maintainability of system, customized or extended.

General properties for electric motors to be tested

that are covered by the testing system:

Insulating performance , capacitance , hanger , ripple

current, Hall, forward & reverse rotation performance ,

with or without cushion pads and the like as well as

the integrated test for anti-pinch electric motors.

Related Software and Major

Function Modules of Testing System

| Software Type | Major Function Modules | Installation location |

| Testing Software | System operating environment self-test |

IPC |

| System equipment calibration before test |

||

| System equipment parameter setting |

||

| Standard process values update by automatic download (the network under normal circumstances) |

||

| Motor properties testing | ||

| Test data storage(local / remote) | ||

| Graphical display of test results | ||

| Motor under test pass rate statistics |

||

| Defective motor unanticipated overflow prevention |

||

| Continuous defective motor alarm | ||

| …… | ||

| Process value setting software |

Standard process valuesremote / local setting |

Process Engineer working computer |

| …… | ||

| Data query and statistical software |

Test Data Statistics View | |

| …… |

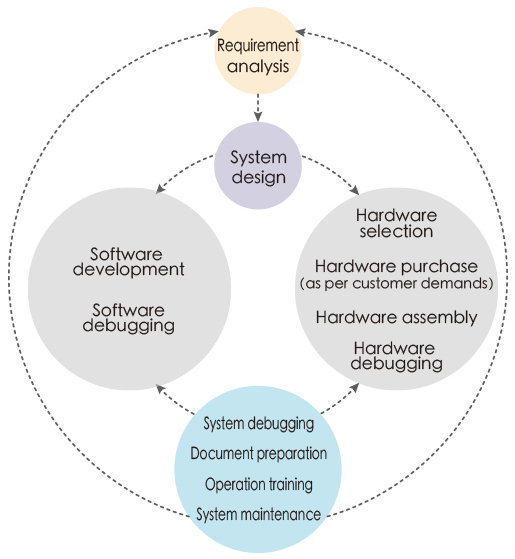

Service Process